Design Capacity

As a prominent Chinese supplier of tools and dies for steel wheel manufacturing, Xiaoya owns a provincial enterprise technology center and post-doctoral research center, as well as a tool and technological equipment research center with more than 20 senior tooling R&D engineers and over 50 skilled and experienced engineering and technological employees.

The tooling research institution specializes in the design and development of dies, gauges, fixtures, and welding stations for different types of steel wheel spokes and rims, as well as the design and development of stamping dies.

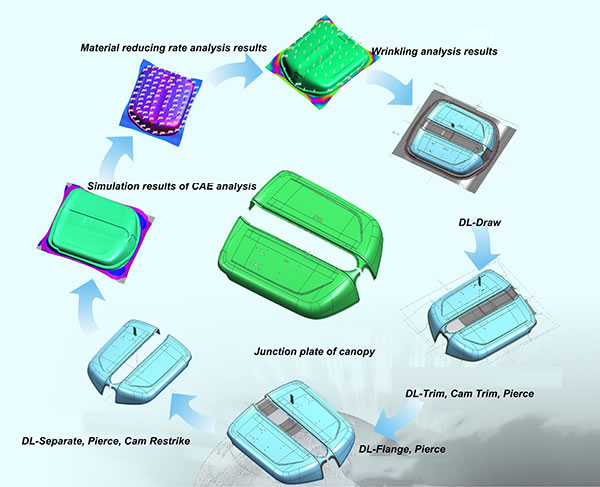

Our technological equipment research institution specializes in the design of manufacturing technology for wheel production lines. It uses CAD/CAE/CAM design and analysis software, as well as reverse engineering and 3D design. This achieves a virtual design of wheel rims and spokes, effectively ensuring the product quality and reducing the manufacturing cycle.

-

Tooling Research Institution

Tooling Research Institution -

Technological Equipment Institution

Technological Equipment Institution

We are committed to the process and design of stamping products made from high strength plates and thick plates. Using software like AUTOFORM and ThinkDesign, and combining that with our years of experience, we have successfully developed a parametrized springback compensation solution for auto parts made from high strength plates.

Combining CAE stimulated analysis technics, we have optimized a die design scheme and process layout, which provides powerful technological support for the design and manufacturing of stamping tools.

Our company can independently design and manufacture different steel wheel spoke dies and wheel rim dies based on customer drawings, processes and equipment. We can also implement reverse engineering according to the product samples provided by customers. We can formulate reasonable process routes and design the die structure depending on customer’s requirements for production equipment and quality.

Standardized Design

In regards to the universal parts of dies such as springs, guideposts, guide sleeves, locating pins, fastening bolts, and other parts, we have a standardized design system and database of standardized parts, which improves the standardized design level.

Patents

As a specialist designer and manufacturer of tooling for steel wheel spokes and wheel rims manufacturing machines, we have over 30 national patents on tooling R&D, including patents for invention, utility model patents, and design patents.