Chinese Specialist Wheel Rim Machinery Designer and Manufacturer

Xiaoya Precise Machinery Co., Ltd, is one of China's specialist manufacturers of steel wheel rim manufacturing lines and tooling for the production of vehicle wheels. With a complete product portfolio, and a history of innovation, we have been providing excellent products, including coiler machines, flash butting welding machines, trimmer, planisher and end cutting machines, horizontal flaring machines, roll forming machines, horizontal expanding machines, valve hole punching presses, as well as tooling for wheel spokes and rim manufacturing. Backed by our parent company of Xiaoya Group, we can offer our wheel machinery and dies to companies looking to make steel wheels on passenger cars at 12 to 17 inches, commercial vehicle at 17.5 to 26 inches, agricultural vehicle at 20 to 54 inches, and engineering vehicles. We can also carry out OEM services, custom production solutions, and design and manufacturing solutions for dies and stamping tools. Please feel free to contact us.

-

-

Coiler Machine for Wheel Rim

The discharge end can be designed with an automatic discharging platform that is conducive to the automatic transportation of the work piece.

The wheel rim coiler machine features an integrated design, that melds deburring, stamping and coiling into one machine, saving labor and floor space. -

-

Roll Forming Machine

Roll forming machine is also known as a wheel rim forming machine, and is used for symmetrical or asymmetrical roll forming of steel wheel rims. The roll forming equipment consists of the main machine, hydraulic transmission system, pneumatic system, PC control system and lubrication system.

-

-

Horizontal Expanding Machine

It is an important piece of wheel rim machinery for expanding and sizing the rim after the roll forming process. The molds on the expanding equipment are specially designed for easy disassembly. When changing the molds, they can be lifted out integrally, which saves time.

-

-

Tooling for Wheel Spoke Manufacturing

Xiaoya has developed tools and dies for high strength plate wheel spokes and disc manufacturing that are suitable for automatic wheel spoke stamping lines. According to the production process, there are 7 sets of dies in a complete wheel spoke profiling

-

-

Tooling for Wheel Rim Manufacturing

It has a split structure that makes change and maintenance easy. The tooling for wheel rim manufacturing is made of Cr12MoV and other materials. With a vacuum thermal treatment after rough machining, its hardness is up to more than HRC60.

-

-

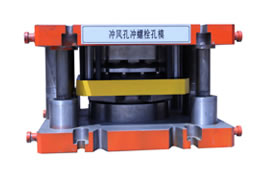

Stamping Tools

Stamping dies and press tools we supply include drawing dies, flanging dies, punching dies and more. They provide excellent advantages to the manufacturers of automobile stamping parts, including high precision, reliable quality, and low investment cost.