Steel Wheel Rim Manufacturing Process

Here at Xiaoya Group, we offer customers complete production lines and single machines for the production of steel wheel rims. Our wheel rim machinery is used to make steel wheel rims for cars, trucks, buses, tractors, farm vehicles and construction vehicles. As a professional manufacturer of wheel rim manufacturing equipment, we can design and make steel wheel rim manufacturing lines for the production of 10 to 54 inch wheel rims.

Advantages

1. Labor and Space Efficient Layout:According to production processes from rim band coiling to butt welding, trimming, flaring and roll forming, and expanding sizing, these steel wheel rim lines have a compact, efficient and labor saving layout, saving production areas for users and allowing easy logistical arrangements.

2. High Automation and Low Rejection Rate:Xiaoya steel wheel rim production lines use PLC control systems and mechanical arm transport systems to ensure the high automation, which improves the working efficiency, reduces labor intensity, and lowers labor costs.

Through in-depth design, accurate positioning, and precise processing, the wheel rim manufacturing line guarantees the high quality end products and effectively controls the rejection rate, within 0.5%.

3. Remote Control and Maintenance:PLC control systems carry out a fast transmission of production data using remote control technology, making it convenient for controlling production processes. In addition, the steel wheel rim line can achieve remote control maintenance via an internet connection, making daily maintenance and inspection easy.

Main Specifications

According to wheel rim categories, diameters and production processes, we can design and manufacture small, large and ultra-large wheel rim manufacturing lines. The processing range of the lines can be adjusted according to customer’s requirements.

1. Passenger cars Wheel Rim Line

For production of passenger car wheel rims

Diameter: 12~17"

Width: 3-10"

Steel plate thickness: ≤4mm

2. Truck Wheel Rim Line

For production of tubeless wheel rims of trucks

Diameter: 17.5~26"

Width: 5.5-16"

Steel plate thickness: ≤8mm

3. Farm vehicle Wheel Rim Line

For production of wheel rims of farm vehicles, construction vehicles and tractors

Diameter: 20~54"

Width: 7-28"

Steel plate thickness: ≤8mm

Operation Modes

In accordance with user's production requirements, Xiaoya supplies semi-automatic steel wheel rim manufacturing line and fully automatic steel wheel manufacturing lines. The first needs 10 to 12 people to operate it, completing material loading and unloading, as well as machining operations. The fully automatic one only needs 3-5 operators as feeding and discharging are all automatic, and achieves an automatic operation and material transportation.

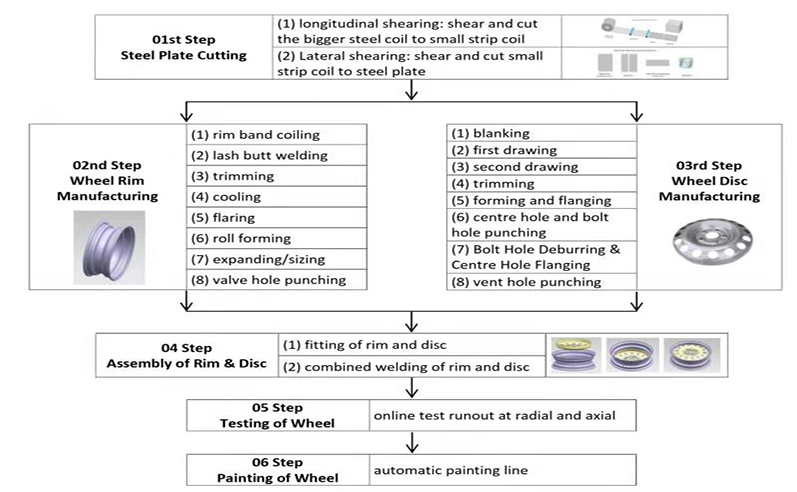

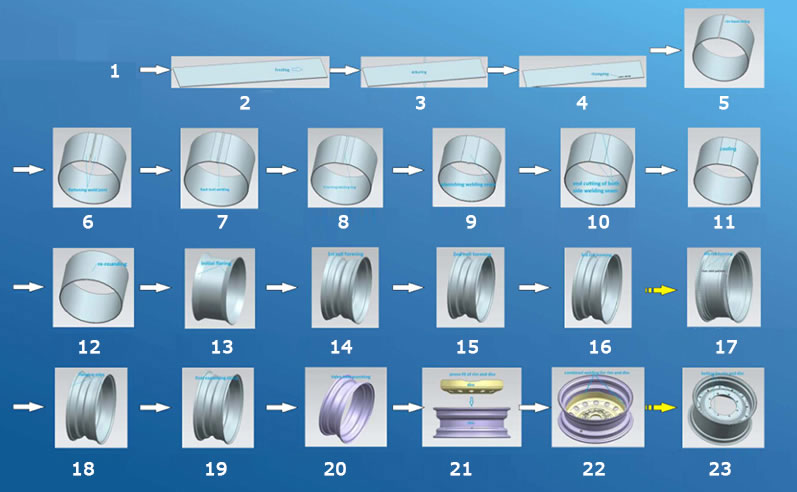

Process Arrangement of Wheel Rim Production Lines

The production process arrangement of the steel wheel rim line is based on the steel plates that customers use. These steel plates have been cut to length by the steel supplier.

We can design the most appropriate layout of the production process and machining technology according to user’s requirements. Conventional production processes of the passenger car, truck and farm vehicle wheel rim lines are shown in the following table for reference.

| No. | Process | Rim workpiece picture | Passenger car | Truck | Farm vehicle |

| 1 | Steel plate feeding | √ | √ | √ | |

| 2 | Deburring for both side | √ | √ | √ | |

| 3 | Mark stamping | √ | √ | √ | |

| 4 | Rim band coiling | √ | √ | √ | |

| 5 | Flattening weld joint | Note1, optional | √ | √ | |

| 6 | AC flash butt welding | √ | √ | √ | |

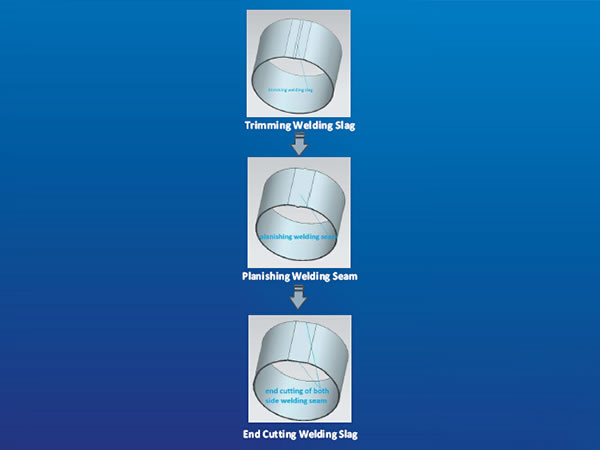

| 7 | Trimming welding slag | √ | √ | √ | |

| 8 | Planishing welding seam | √ | √ | √ | |

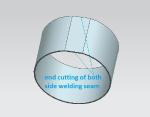

| 9 | End cutting of welding slag | √ | √ | √ | |

| 10 | Cooling | √ | √ | √ | |

| 11 | Re-rounding | √ | √ | √ | |

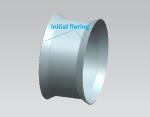

| 12 | Initial flaring | √ | √ | √ | |

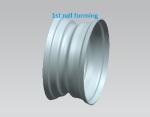

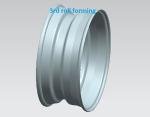

| 13 | 1st roll forming | √ | √ | √ | |

| 14 | 2nd roll forming | √ | √ | √ | |

| 15 | 3rd roll forming | √ | √ | √ | |

| 16 | 4th roll forming for non-skid pattern | Note2, no-need | Note2, no-need | √ | |

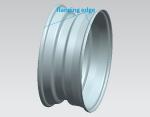

| 17 | Edge flanging | Note3, optional | Note3, optional | Note3, optional | |

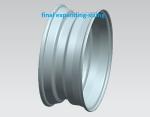

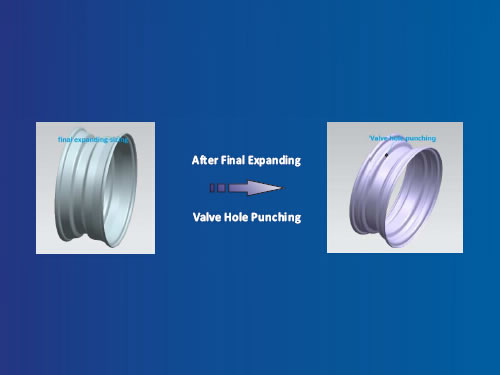

| 18 | Final expanding-sizing | √ | √ | √ | |

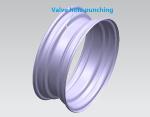

| 19 | Valve hole punching | √ | √ | √ | |

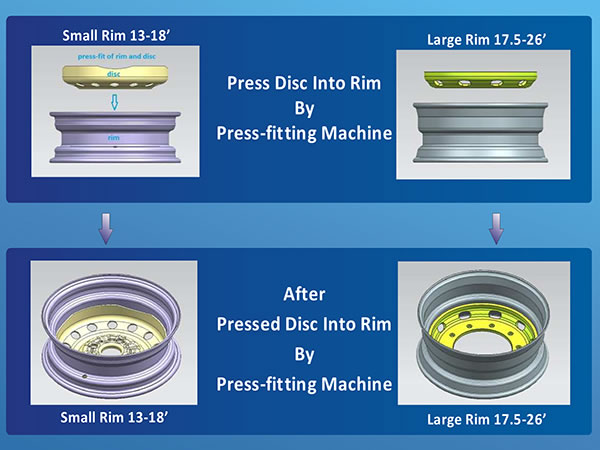

| 20 | Pressing disc into rim | √ | √ | Note4, no-need | |

| 21 | Combined welding for rim and disc | √ | √ | Note4, no-need | |

| 22 | Bolting for rim and disc | Note4, no-need | Note4, no-need | √ |

**NOTES

#1.Generally, the passenger cars wheel rim line does not need to flatten the welding joint. However, if it is used to produce small construction car wheel rims with a thickness of more than 4mm, this wheel rim equipment needs to undergo flattening.

#2. Passenger cars wheel rim Line and truck wheel rim line don’t require roll forming for non-skid patterns that are used to increase the abrasion between the rim and the tire.

#3. Edge flanging is an elaborate cold rolling processes for keeping two edges of the wheel rim smooth and burr free. It is optional for users according to their requirements for machining precision.

#4. The wheel rims produced on the passenger cars and truck wheel rim lines are often jointed with wheel discs in a welding process, while those produced in farm vehicle wheel rim lines are generally connected to the wheel disc using bolts.

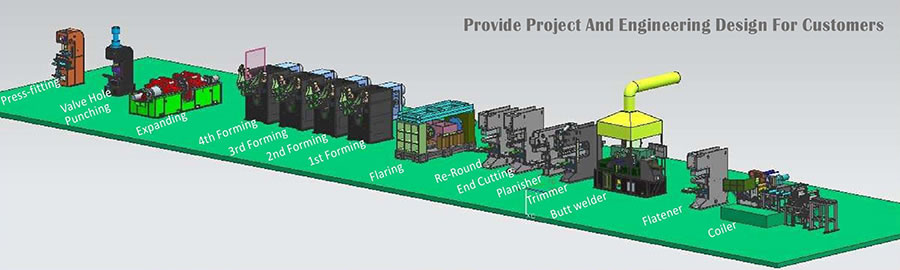

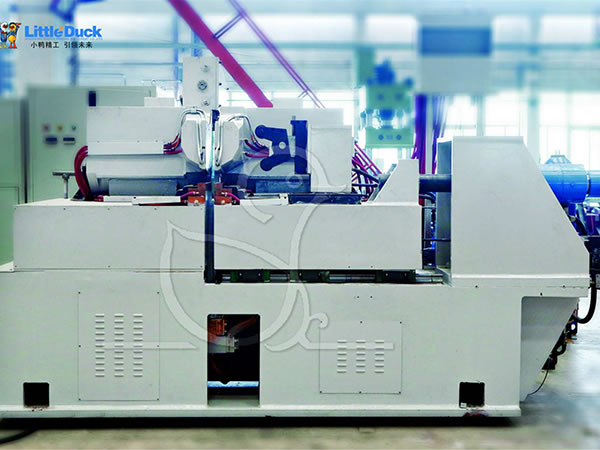

Main Production Equipment

Our steel wheel rim manufacturing line consists of a wide range of wheel machinery including a coiler machine, AC flash butt welding machine, trimmer-planisher-end cutting unit, re-rounding press, horizontal flaring machine, and roll forming machine, horizontal expanding machine, and valve hole punching press, press-fit machine, combined welding machine, hydraulic system, electrical control system and necessary tooling.

Rims are incredibly important to the entire wheel component, which means rim manufacturing plays a crucial role in the production of wheels. Xiaoya’s steel wheel rim manufacturing line is used to manufacture wheel rims for passenger cars, trucks, buses, tractors, farm vehicles, and construction vehicles' wheels. According to user’s requirements, we can design and manufacture the rim production line to make 10 to 54 inch steel wheel rims.

| 1. Low Carbon Steel Strip Cut-to-length Customer Supplied

2. Rim band feeding 3. Deburring for both sides 4. Stamping mark 5. Rim band coiling 6. Flattening weld joint 7. AC flash butt welding 8. Trimming welding slag 9. Planishing 10. End cutting 11. Cooling |

12. Re-rounding

13. Initial flaring 14. 1st roll forming 15. 2nd roll forming 16. 3rd roll forming 17. 4th roll forming for non-skid pattern 18. Edge flanging 19. Final expanding 20. Valve hole punching 21. Press disc into rim 22. Combined welding for rim and disc 23. Bolting rim and disc |

A coiler machine is an essential machine that is used before the rim welding. It provides the forms for coiled hoops from flat rim bands. It can be used in the preparation of wheels for light weight cars, trucks, construction vehicles, farm vehicles and more. After the feeding, deburring, stamping and auto coiling, the rim band will become a coiled hoop.

It is necessary to use the flattening machine to flatten the joint of the coiled rim bands that are over 4mm thick before proceeding to the flash butt welding process.

The welding slag will be produced on both the inside and outside surface of the weld joint after the welding process. A special machine unit comprised of the trimmer,planisher and end cutting machine can be used to remove the slag and make the surface of the weld joint flat and smooth.

After the weld joint processing, cooling, and re-rounding processes, a horizontal flaring machine will be used to flare two edges of the rim to make the following roll forming processes easier.

The roll forming machine is used for the symmetrical or asymmetrical roll forming of wheel rims for passenger cars, tractors and construction vehicles. This machine is used for the 1st through the 4th roll forming. The 4th roll forming process is optional, and is used to press non-skid patterns onto the rim of tractors and construction vehicles.

A horizontal expanding machine is used for the expanding size process after the roll forming of the wheel rims. Precise expanding and sizing using a special tooling allows the formed rims to meet the design requirements for diameter.

Gas tightness detection tests are conducted to ensure the welding quality and reduce air leakage. The valve hole punching is done after profiling, and is an important step in steel wheel rim manufacturing. With a corresponding mold, it can punch the right valve hole on the effective part of the rim. The valve hole punching press is used for the flat pressing and hole punching on tubeless wheel rims.

A steel wheel is made of the wheel rim and the wheel disc. The wheel rim and tire form an airtight unit for bearing the vehicle’s weight and transmitting power. The wheel disc is connected to a hub, and transmits the power from the engine. Usually, the wheel rim and disc of passenger cars and trucks are connected by welding, whereas large wheel rims and discs for farm vehicles are bolted to each other.

Recommended Products