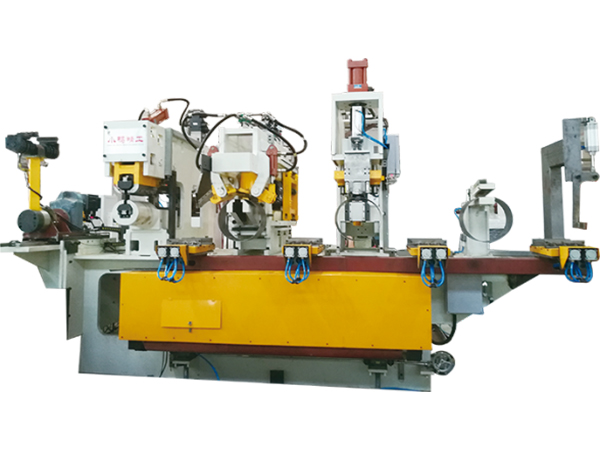

Trimmer, Planisher, End Cutting Machine

The trimmer, planisher, and end cutting machine is also an essential machine for the production of processing weld joints.

Functions of Each Unit

1. The trimmer, also known as the trimming machine, is used to remove weld slag on internal and external surfaces of the weld joint, in order to flatten it.

2. The weld planisher will planish, and reinforce the weld joint after the weld slag on it has been removed.

3. The end cutting machine is used to cut off leftover material at both ends of the weld joint.

Main Features

1. The wheel manufacturing equipment comes with a single piece design and shares one hydraulic system, which reduces the number of needed operators and saves floor space.

2. The automatic feeding and discharging mechanism has a 3 process, and 4 location design, which allows for automatic work piece transportation, ensuring high production efficiency.

3. As optional parts, the automatic feeding and discharging devices feature a split design with the main machine. This makes it easy to change from manual to automatic and vice versa.

4. The cutter and die on the steel wheel rim machine use an easy dismount design, allowing users to quickly change the die, and changing the production of different wheel rims.

| No. | Item | Data | |||

| 1 | Main machine specification | Trimmer |

|

|

|

| Planisher |

|

|

|

||

| End cutting machine |

|

|

|

||

| 2 | Power supply | AC 380V/ 3phase/50Hz | AC 380V/ 3phase/50Hz | AC 380V/ 3phase/50Hz | |

| 3 | Rated input power | 37KVA | 45KVA | 55KVA | |

| 4 | Max. clamping force for trimming | 6Tons | 9Tons | 12Tons | |

| 5 | Max. trimming force | 6Tons | 9Tons | 12Tons | |

| 6 | Max. clamping force for planishing | 6Tons | 9Tons | 12Tons | |

| 7 | Max. planishing force | 6Tons | 9Tons | 12Tons | |

| 8 | Max. cutting force | 28Tons | 40Tons | 53Tons | |

| 9 | Diameter of cutting oil cylinder | 125mm | 200mm | 220mm | |

| 10 | Pressure of hydraulic system | 12Mpa | 12MPa | 14Mpa | |

| 11 | Maximum thickness of rim band | 5mm | 8mm | 13mm | |

| 12 | Width range of rim band | 220mm ~350mm | 300mm ~500mm | 450mm ~800mm | |

| 13 | Diameter range of rim | 280mm ~450mm | 400mm ~650mm | 600mm ~1000mm | |

Main machine specification: Trimmer (BZJ-500B), Planisher (GYJ-500G), End cutting machine (DQJ-500G)

Power supply:AC 380V/ 3phase/50Hz

Rated input power:37KVA

Max. clamping force for trimming:6Tons

Max. trimming force:6Tons

Max. clamping force for planishing:6Tons

Max. planishing force:6Tons

Max. cutting force:28Tons

Diameter of cutting oil cylinder:125mm

Pressure of hydraulic system:12Mpa

Maximum thickness of rim band:5mm

Width range of rim band:220mm ~350mm

Diameter range of rim:280mm ~450mm

Main machine specification: Trimmer (BZJ-600B), Planisher (GYJ-600G), End cutting machine (DQJ-600G)

Power supply:AC 380V/ 3phase/50Hz

Rated input power:45KVA

Max. clamping force for trimming:9Tons

Max. trimming force:9Tons

Max. clamping force for planishing:9Tons

Max. planishing force:9Tons

Max. cutting force:40Tons

Diameter of cutting oil cylinder:200mm

Pressure of hydraulic system:12MPa

Maximum thickness of rim band:8mm

Width range of rim band:300mm ~500mm

Diameter range of rim:400mm ~650mm

Main machine specification: Trimmer (BZJ-800B), Planisher (GYJ-800G), End cutting machine (DQJ-800G)

Power supply:AC 380V/ 3phase/50Hz

Rated input power:55KVA

Max. clamping force for trimming:12Tons

Max. trimming force:12Tons

Max. clamping force for planishing:12Tons

Max. planishing force:12Tons

Max. cutting force:53Tons

Diameter of cutting oil cylinder:220mm

Pressure of hydraulic system:14Mpa

Maximum thickness of rim band:13mm

Width range of rim band:450mm ~800mm

Diameter range of rim:600mm ~1000mm

Related Names

Trimming Machine | Planishing Machine